Sizes and pump construction, Graco Pumps 716, 1050, 1590, 2150 and 3275

Graco Pumps have many applications in the Food, General industry, Chemical and the Motor industry, from low to high flow transfer rates.

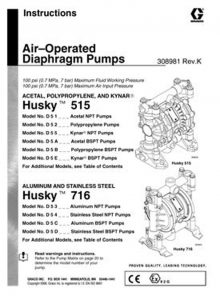

- Graco Pumps 3/4″ Aluminium or Stainless Steel

- Graco Pumps 1″ Aluminium or Stainless Steel

- Graco Pumps 1-1/2″ Aluminium or Stainless Steel

- Graco Pumps 2″ Aluminium, Cast Iron or Stainless Steel

- Graco Pumps 3″ Aluminium

There is a wide range of optional construction materials for internal Seats, Balls and Diaphragms to suit your applications, and are ATEX rated

Flow rates

Maximum flow rates vary from 61 litres per minute for the 3/4″ pump to 1.041 litres per minute for the 3″ pump.

Effects of viscosity and suction lifts on flow rates

These are very important factors when considering the use of a Graco Double Diaphragm pump.

When to use Double Diaphragm pumps, considering the viscosity and the pressures involved

Double Diaphragm pumps are designed for volume transfer applications and are usually unsuitable for very viscous products or where there are long pipe runs and high discharge heads to overcome.

FES can supply special pumps for working under these more difficult conditions. If you are unsure which is the best pump for your application, call the experts at FES.

Air valves

Graco have developed very reliable air valves with the number of working parts reduced to a minimum.

Spares

Spares for wetted parts are available in a variety of kits for convenience when replacing wearing parts in pumps. Or go to Applegate, 1st Directory or Findtheneedle.